factory Outlets for China 175L 2.0MPa Vertical Welded Heat Insulated Liquid Gas Dura Cylinders Cryogenic Storage Dewar Tank

The key to our success is “Good Solution Top quality, Reasonable Value and Efficient Service” for factory Outlets for China 175L 2.0MPa Vertical Welded Heat Insulated Liquid Gas Dura Cylinders Cryogenic Storage Dewar Tank, Adhering to your small business principle of mutual positive aspects, we have now won superior popularity among our customers because of our best solutions, excellent products and competitive selling prices. We warmly welcome clients from your home and overseas to cooperate with us for common achievement.

The key to our success is “Good Solution Top quality, Reasonable Value and Efficient Service” for China Cryogenic Storage Dewar, Cryogenic Dewar, We critically promise that we deliver all the customers with the best quality solutions, the most competitive prices and the most prompt delivery. We hope to win a resplendent future for customers and ourselves.

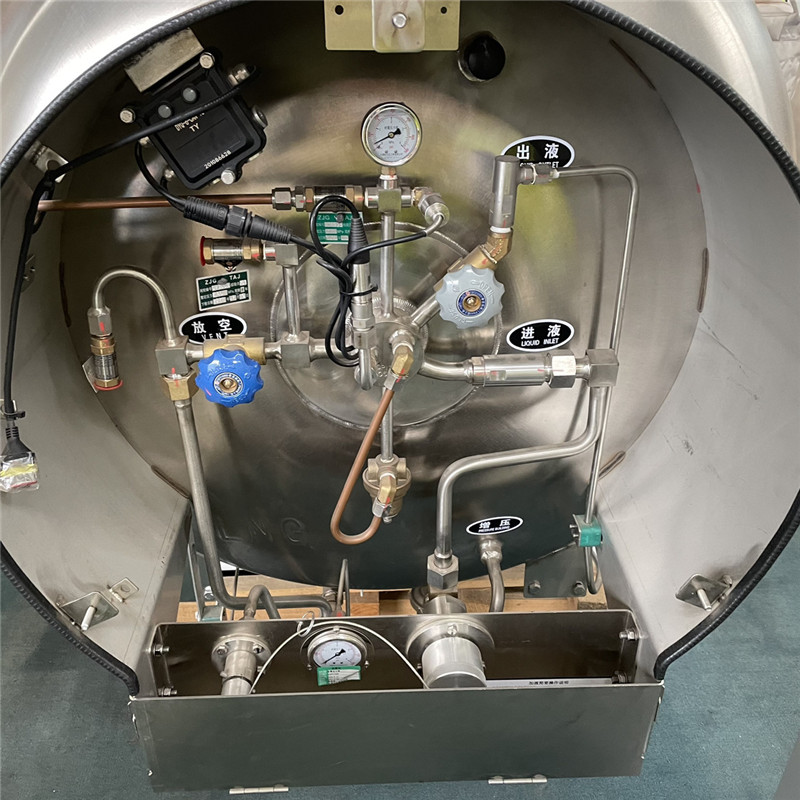

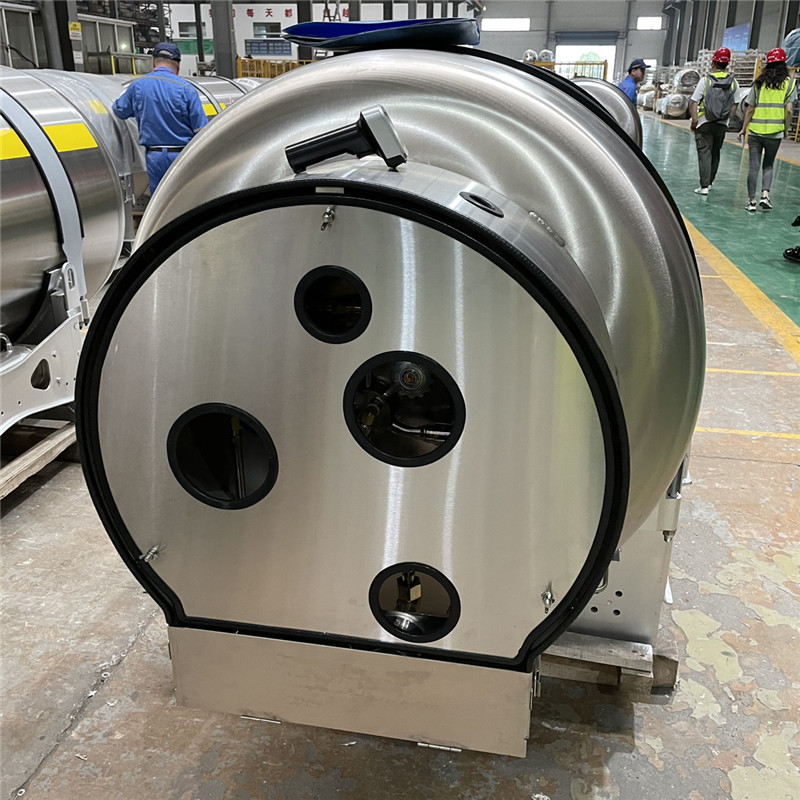

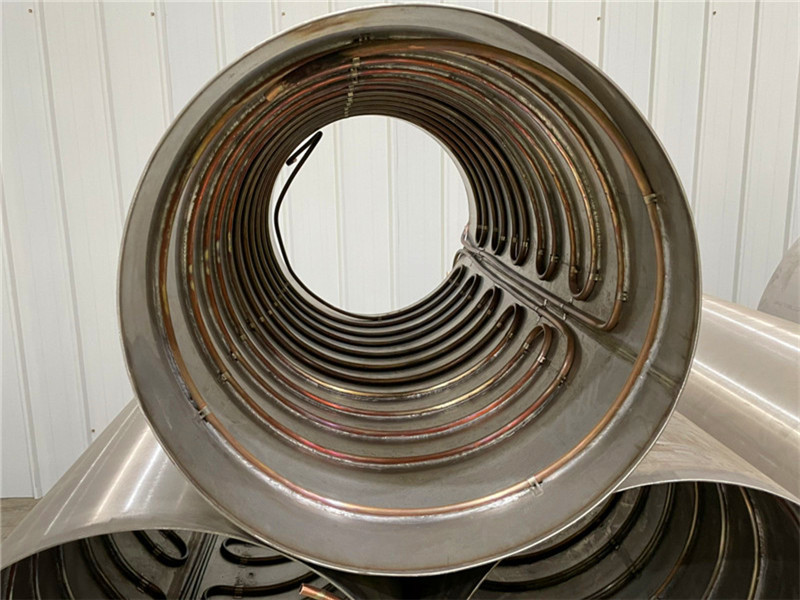

Vehicle LNG storage tank refers to a high-vacuum insulated container for storing LNG on a vehicle. Designed with a double-layer (vacuum) structure. The inner tank is used to store low-temperature liquid LNG. The outer wall is wrapped with multiple layers of thermal insulation material, which has super thermal insulation performance. At the same time, the jacket (the space between the two layers of containers) is pumped into a high vacuum to form a good Adiabatic system. The design of the shell and the support system can withstand the relevant external forces generated by the transportation vehicle when driving.

Parameter

|

Product No. |

LNG Cylinder for vehicle |

|||||||||

|

CDPW500 |

CDPW500 |

CDPW500 |

CDPW500 |

CDPW500 |

CDPW500 |

CDPW500 |

CDPW500 |

CDPW500 |

CDPW500 |

|

|

Dimension mm |

Φ556×1159 |

Φ556x 1209 |

Φ556x 1259 |

Φ556x 1284 |

Φ556x 1309 |

Φ556x 1334 |

Φ556x 1361 |

Φ556x 1412 |

Φ556x 1439 |

Φ556x 1464 |

|

Norminal Volume L |

150 |

160 |

170 |

175 |

180 |

185 |

190 |

200 |

205 |

210 |

|

Effective Volume L |

135 |

144 |

153 |

157.5 |

162 |

166.5 |

171 |

180 |

184.5 |

189 |

|

Net Weight Kg |

131 |

136 |

141 |

143 |

145 |

148 |

150 |

155 |

158 |

160 |

|

Maximum filling capacity Kg |

49 |

52 |

56 |

57 |

59 |

61 |

62 |

66 |

67 |

69 |

|

Weight with gas Kg |

180 |

188 |

196 |

200 |

204 |

208 |

213 |

221 |

225 |

229 |

|

Static evaporation rate%/d |

≤2.90 |

≤2.70 |

≤2.50 |

≤2.40 |

≤2.38 |

≤2.36 |

≤234 |

≤2.30 |

≤2.30 |

≤2.29 |

|

Working pressure MPa |

1.59 |

|||||||||

|

Testing Pressure MPa |

3.18 |

|||||||||

|

Design temperature℃ |

-196 |

|||||||||

|

Opening pressure of main relief valve MPa |

1.6 |

|||||||||

|

Opening pressure of auxiliary safety valve MPa |

2.41 |

|||||||||

|

Filling medium |

LNG(liquified natural gas) |

|||||||||

|

Air flow volume Nm3/h |

60~120 |

|||||||||

|

Economic regulator setting value MPa |

0.965 |

|||||||||

|

Pressure display method |

Pressure gauge and pressure sensor |

|||||||||

|

Surface treatment |

Polishing |

|||||||||

|

Level gauge form |

Capacitance level gauge |

|||||||||

|

Base structure |

Saddle support |

|||||||||

|

Material |

Austenitic stainless steel (06Cr19Ni10 or 304) |

|||||||||

Product Details

Production Process

Main production process: cylinder forming, head welding, winding emptying, polished cold test, frame assembly, package inspection.

Product advantages

1.Long term heat preservation: high vacuum degree, low exhaust frequency, two years vacuum guarantee, better than competitors

2.High Safety: There is no leakage while using. It is not dangerous when being baked in fire for 40 mins, dropping down from 10 m height, hit by 100km/h. The gas cylinder frame fit the special installation requirements of the LNG automobiles and adapt to any complex conditions.

3.High stability: The gas cylinder output pressure in the gas supply system and matching degree of the valves is more stable

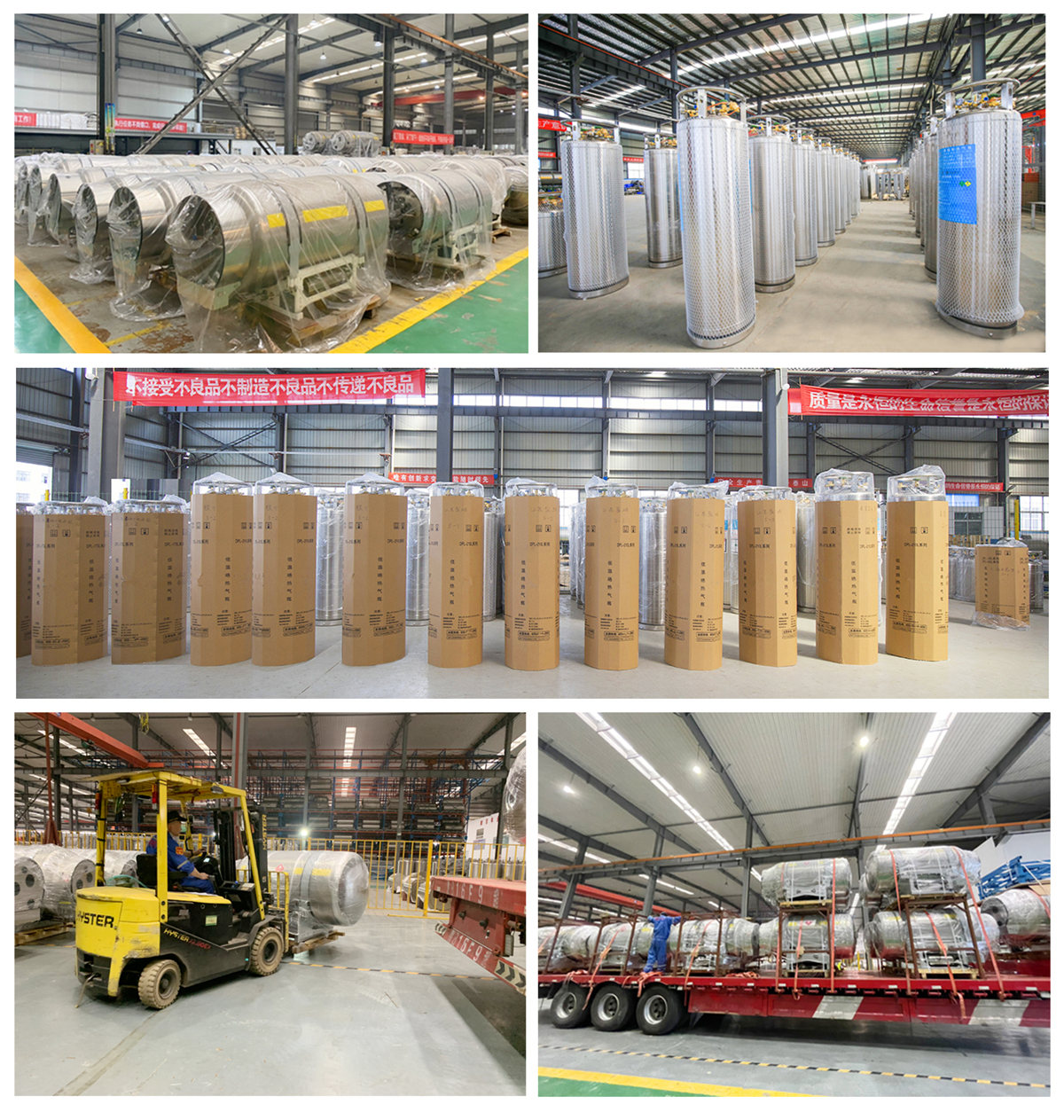

Package&Delivery

Our regular packaging is carton, wooden box, iron frame. If you have special requirements, we can also negotiate.

Factory

With 20 years of experience, our products have been popular all over the world, such as Russia, Ukraine, Mexico, Australia, Uzbekistan, Italy, Germany, etc..

FAQ

How to ensure your cylinders quality?

HANSHENG supplies dewars to safely contain liquefied gases such as nitrogen, oxygen, argon and carbon dioxide, which are for industry and commerce use. These gases are stored at extremely low temperatures and in a liquid state.

How many different specifications of insulated welded cylinders (Dewars) does HANSHENG have?

We produce Insulated Welded Cylinders (Dewars) with different specifications from 150L-898L

What is the ideal working pressure of LNG Vehicle cylinder?

The ideal working pressure is 0.8 Mpa – 1.2 Mpa, while the nominal working pressure is 1.59 Mpa.

What is the warranty of your Products?

The warranty for the vacuum of equipment is 3 years from the date of sale.

All components come with a limited 1 year manufacturer warranty on defects in material or workmanship from the date of purchase to the original owner.

What are some methods of payment?

T/T, L/C, as well as Paypal are supported.

The key to our success is “Good Solution Top quality, Reasonable Value and Efficient Service” for factory Outlets for China 175L 2.0MPa Vertical Welded Heat Insulated Liquid Gas Dura Cylinders Cryogenic Storage Dewar Tank, Adhering to your small business principle of mutual positive aspects, we have now won superior popularity among our customers because of our best solutions, excellent products and competitive selling prices. We warmly welcome clients from your home and overseas to cooperate with us for common achievement.

factory Outlets for China Cryogenic Storage Dewar, Cryogenic Dewar, We critically promise that we deliver all the customers with the best quality solutions, the most competitive prices and the most prompt delivery. We hope to win a resplendent future for customers and ourselves.