Bottom price Cryogenic Vessel - 175L Middle Pressure Liquid Oxygen/Nitrogen Cryogenic Cylinder – Hansheng

Bottom price Cryogenic Vessel - 175L Middle Pressure Liquid Oxygen/Nitrogen Cryogenic Cylinder – Hansheng Detail:

DPL series welded insulated gas cylinders use high-quality imported insulation materials, unique vacuum insulation technology, and excellent thermal insulation performance. They can provide a long storage time, extremely low daily evaporation rate, and high gas discharge flow. Life cycle cost. DPL series welded insulated gas cylinders adopt a modular design. The volume ranges from 80L to 232L. The working pressure is divided into 3 levels, namely the medium pressure series (working pressure 1.38MPa, marked as MP), and the high pressure series (working pressure is 2.3MPa, marked as HP), ultra-high pressure series (working pressure is 2.88MPa, marked as VP), customers can make the best choice according to the usage.

Parameter

|

Product No. |

DPL450- 80-1.38Ⅰ |

DPL450- 100-1.38Ⅰ |

DPL450- 150-1.38Ⅰ |

DPL450- 175-1.38Ⅰ |

DPL450- 195-1.38Ⅰ |

DPL450- 210-1.38Ⅰ |

DPL450- 232-1.38Ⅰ |

|

|

Dimension |

Φ |

Φ |

Φ |

Φ |

Φ |

Φ |

Φ |

|

|

Wright(Empty cylinder) |

75 |

83 |

105 |

116 |

124 |

130 |

138 |

|

|

Working pressure |

1.38 |

|||||||

|

Normal working pressure MPa |

0.52~1.38 |

|||||||

|

Design pressure |

0.52~1.03 |

|||||||

|

Safety valve open pressure Mpa |

1.59 |

|||||||

|

Bursting pressure of bursting disc |

2.41 |

|||||||

|

Volume |

80 |

100 |

150 |

175 |

195 |

210 |

232 |

|

|

effective volume |

72 |

90 |

135 |

157.5 |

175.5 |

189 |

208.8 |

|

|

Maximum filling volume Kg |

O2 |

75 |

93 |

140 |

163 |

182 |

195 |

216 |

|

Nitrogen |

52 |

66 |

98 |

115 |

128 |

138 |

152 |

|

|

Argon |

90 |

113 |

170 |

198 |

221 |

238 |

263 |

|

|

LNG |

|

|

50 |

58 |

65 |

70 |

77 |

|

|

Gas flow |

9.2 |

|||||||

|

Static evaporation rate of liquid nitrogen |

≤2.9 |

≤2.8 |

≤2.5 |

≤2.1 |

≤2.02 |

≤1.99 |

≤1.93 |

|

|

Liquid level gauge form |

Liquid Level Gauge |

|||||||

|

surface treatment |

Polishing |

|||||||

|

Understructure |

Rubber ring |

|||||||

Feature

1. It is an ideal container for storing cryogenic liquids such as liquid oxygen, liquid nitrogen, liquid argon, liquid carbon dioxide, and liquefied natural gas.

2. It is safer and more cost-effective than using ordinary gas cylinders, which improves your market competitiveness.

3. The use of unique structural design and special heat preservation technology, and the use of all imported heat preservation materials, make the product excellent heat preservation performance.

4. The buoyancy type visual level gauge is adopted, and the quality is stable.

5. The inner and outer tanks are made of austenitic stainless steel, providing a durable and firm structure.

6. The outer body adopts thicker stainless steel plate, which has strong impact resistance.

7. The stainless steel shell is polished.

8. The imported valve configuration is adopted, and the reliability is stronger.

9. The use of integrated pressure control combination regulator, only has the function of self-pressurization control valve and economic valve, it is very convenient to use. Bottle body 10. There is a complete information display system on the outside, providing a full range of safe operation guidelines.

11. The high-strength spray anti-rust frame can meet the different requirements of lifting and forklift movement at the same time.

12. According to customer needs, vertical and horizontal cryogenic gas cylinders can be provided.

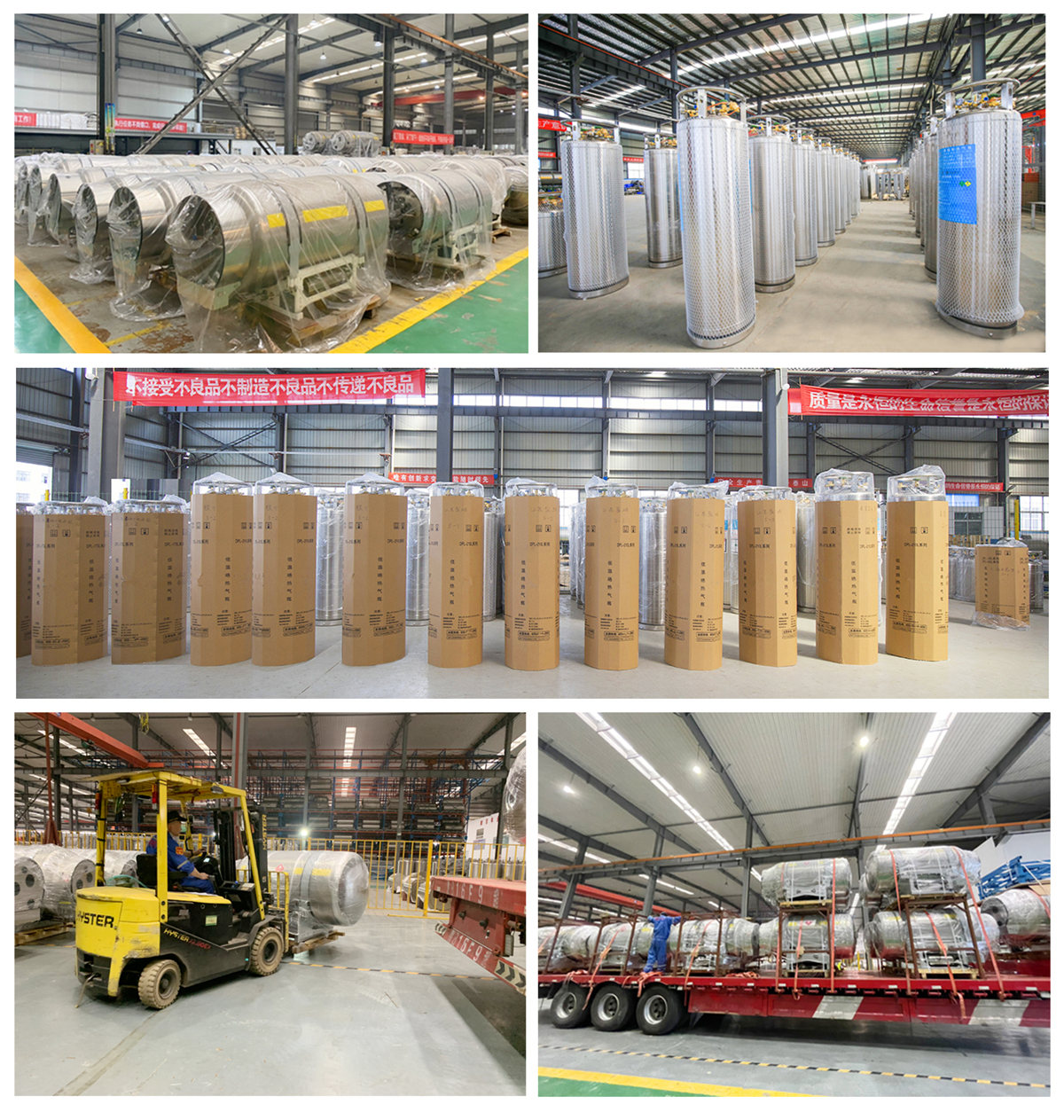

Production Process

Deliver Goods

FAQ

What products you can provide ?

We specialize in producing LPG cylinder, LNG cylinder, Cryogenic Liquid Storage Tank (LO2, LN2, LAr, LCO2 and LNG), etc. Any interests you can feel to contact us for details. Thanks.

What is your production standard?

Our company has obtained the A2 and C2, C3 Pressure Vessel Fabrication Certificates.

Have you supplied cylinders to any renowned companies?

Our group company is a regular strategic partner of some big gas companies. We have supplied many storage tanks for them with different sizes. The biggest size we ever provided is 3000m3 ordinary pressure storage tank.

What can you guarantee?

Equipment warranty is 12 months from the date on which the equipment is applied successfully into operation, or 14 months from the date on which the equipment has been delivered, whichever comes first.

What certificates can we provide?

ISO9001, ISO11439, IATF16949, ECE R110, EAC RUSSIA, etc..

Generally speaking, our cryogenic storage tanks can work normally for 15-20 years.

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is definitely the persistent conception of our corporation to the long-term to establish alongside one another with customers for mutual reciprocity and mutual profit for Bottom price Cryogenic Vessel - 175L Middle Pressure Liquid Oxygen/Nitrogen Cryogenic Cylinder – Hansheng , The product will supply to all over the world, such as: Benin, Austria, Belize, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products we offer, effective and satisfying consultation service is supplied by our specialist after-sale service group. Solution lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we are going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!